With innovative techniques of capturing, training analysis of data, FEDASEN has developed an automated Road Asset Analyser and Pavement & Defect Analyser. This fully automated system has eliminated any manual task and human intervention required in Asset Management and Condition Monitoring across the transport network.

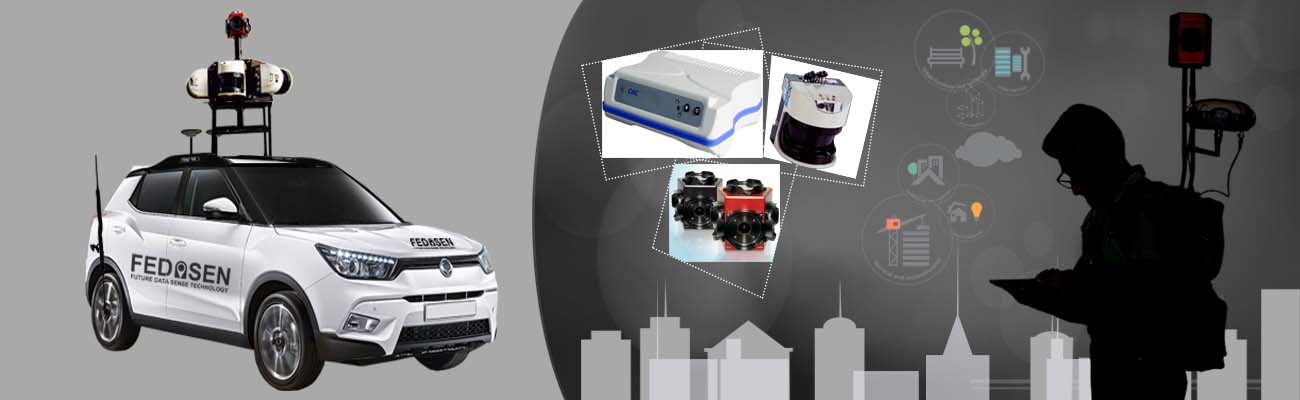

Asset Management and Condition monitoring systems are developed and offered as integrated and end-to-end solutions.

At the infrastructure level, we have core Systems, cloud-based services, hardware and data capturing equipment., By applying Machine Learning and Deep Learning methods in Training Studios, data is fed into the AI-based engine to be trained for all known objects, signs and defects in transport.

Applied Data Analysis and Artificial Intelligence

The solution also comes with customized user interfaces and pre-defined access level.

Although FEDASEN delivers

As a technology owner, FEDASEN is also able to provide solutions for multiple areas of operations and for councils, infrastructure service providers and overall transport network with a vision to extend to urban planning in

The entire process is fully automated. Once the data is captured, assets and defects are detected, registered and classified automatically, the conditions then get rated according to the defined standards, which can also be modified.

At the next level, through customized and interactive reports, there will be a comprehensive dashboard for condition monitoring. This could be for road signs and symbols as well as surface pavement deformation. As stated earlier, the solution totally removes and replaces any procedures that are done manually by human resources.

FEDASEN Architecture

FEDASEN Data Capturing

FEDASEN has successfully developed an innovative data capturing approach, utilising advanced mobile equipment, high-resolution cameras along with RTK GPS receivers, LiDAR and remote sensing technologies, to rapidly obtain the most accurate data of existing kerbside allocation assets and their exact positions, general information, required meta-data about each type of asset, and their current condition.

The composition and the type of the devices including sensors, cameras, GPS receivers can be customised – in terms of accuracy and the type of data – for each solution to satisfy the requirements set by the customers. For instance, depending on the accuracy requirements for positioning, the system can be configured to use GNSS receivers that have an accuracy level of 0.02-0.2 meters, or RTK receivers to obtain an accuracy level of below 0.02 meters.

Depending on the type of location which requires data capturing (e.g., city centres, highways and suburbs), the desired devices can be mounted on cars, bikes, backpacks or drones, to provide the right mobility for easier data capturing.

FEDASEN Asset Analyser

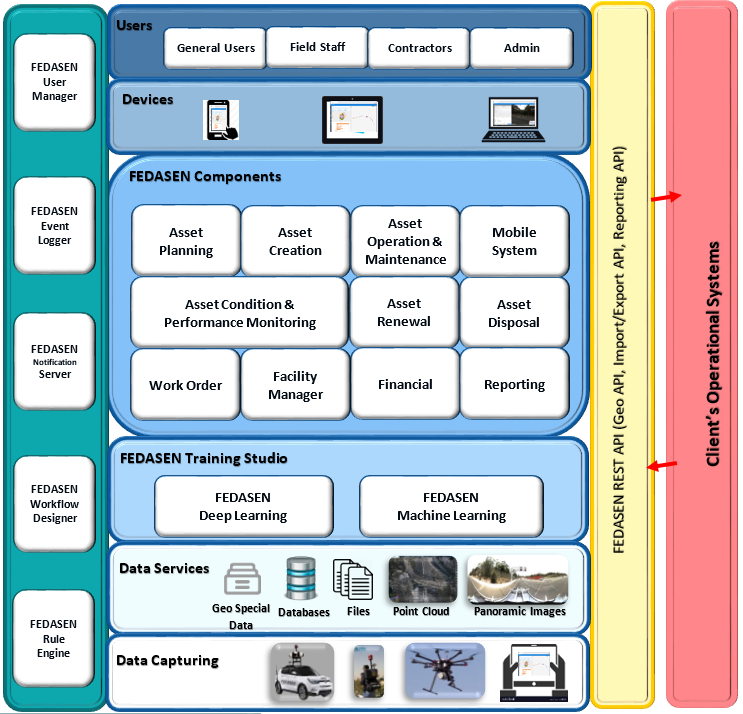

Once all assets and signs are detected and registered, FEDASEN Asset Analyser – a key component of the solution – comes into play. Currently, more than 500 known road assets and signs are detected and classified. FEDASEN Asset Analyser powered by AI (Artificial Intelligence) can then provide a complete condition monitoring of all assets. Every single asset can be viewed through a graphical interface along with its condition.

FEDASEN Condition Monitoring

Although FEDASEN Pavement Analyser and Condition Monitoring has been developed by an exclusive engine and supported by International Standards, it is open and flexible to be adjusted with any other type of standards and regulations. It is currently supported by ASTM Standard – Materials and Consumables in the Road Construction Industry – Asphalt Institute as well as AASHTO Standards and Regulations.

Almost all type of pavement defects, surface deformation, cracks and potholes have been already detected and classified. By applying multiple filters, the system is able to remove any noise, reflection and shadow to have the accurate and exact status of the defect. Pavement Condition Index (PCI) is then automatically applied for condition rating. As mentioned earlier, PCI can be replaced with any other rating method and standard.

Pavement Condition Monitoring can be displayed through interactive reports in customized dashboards. It can deliver a comprehensive view of the entire road and also for any defined segments and distances.

The reports can be generated based on defects type, severity, extent and including all details in terms of positioning.

Reports can also be used for economic analysis. By Decision Making Tree methods, the system identifies whether immediate maintenance is required, or the maintenance can be scheduled. This would be useful for budget forecasting in single or multiple annual plans.

FEDASEN Daily Drive Through

FEDASEN has successfully developed and tested an innovative way of data-capturing that has automated “daily drive-through”, using programmed drones. In this method, unlike common methods that drones are being followed and controlled remotely by a vehicle, the drones are programmed and can fly automatically from the starting point to the defined destination and return to the starting point. Drones, equipped with GPS and sensors, with up to 4 hours of flight at the speed of 70 km per hour, perform data-capturing seamlessly with a significant saving of time and cost, in addition to having high-quality aerial images with accurate geographic coordinates. This procedure could also be used for entire highways, especially inter-state roads, with a complete set of data points.